Author Archives: Ian Fogarty

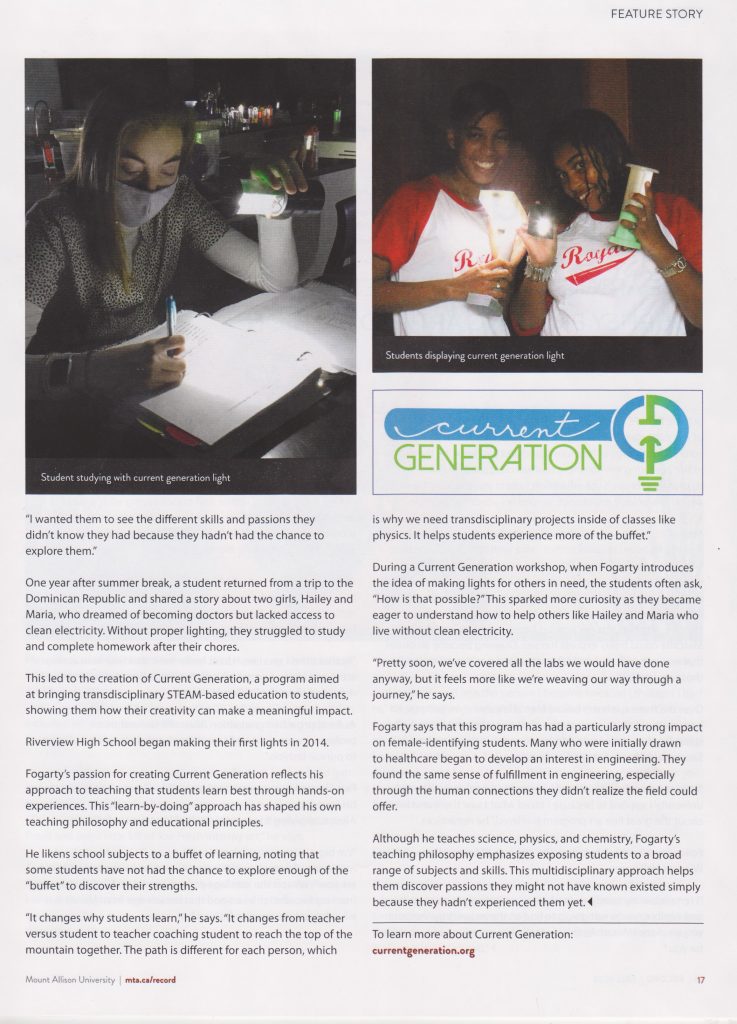

Canada’s #1 university 25 times in the last 30 years, Mount Allison Univ celebrated Current Generation.

Current Gen speaks at NBTA High School Council May 2023

It was a small turnout, but great conversations and multiple requests to visit their school.

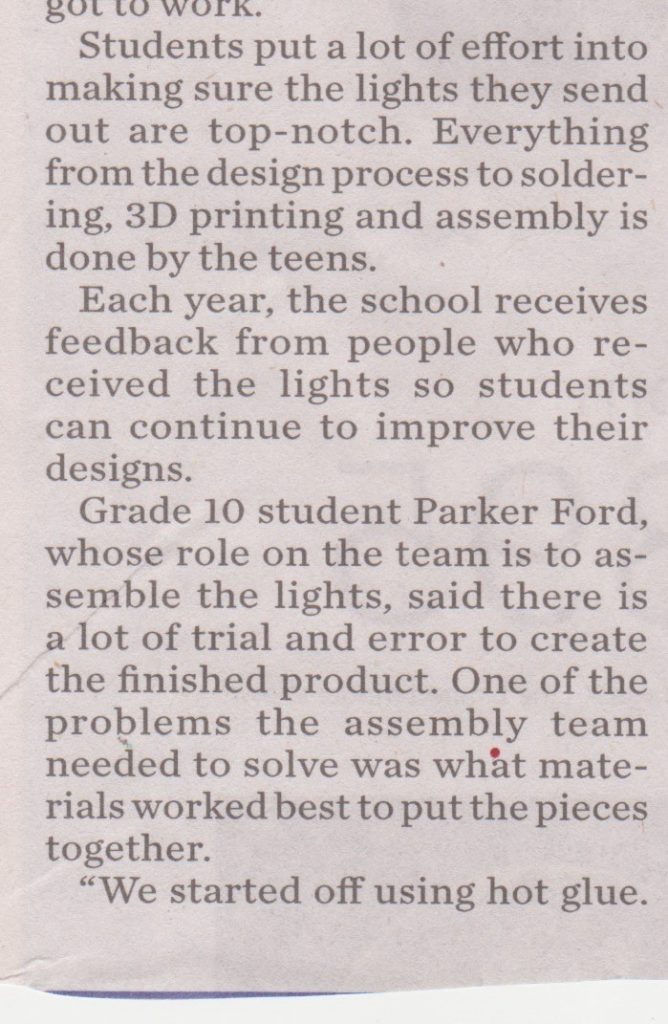

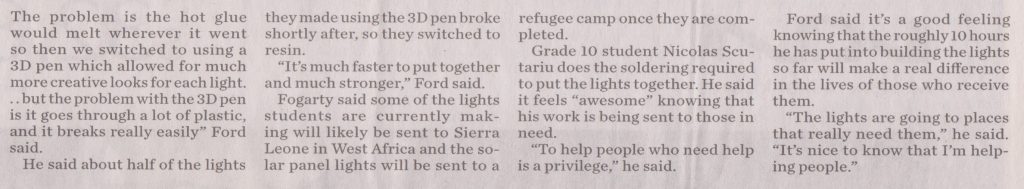

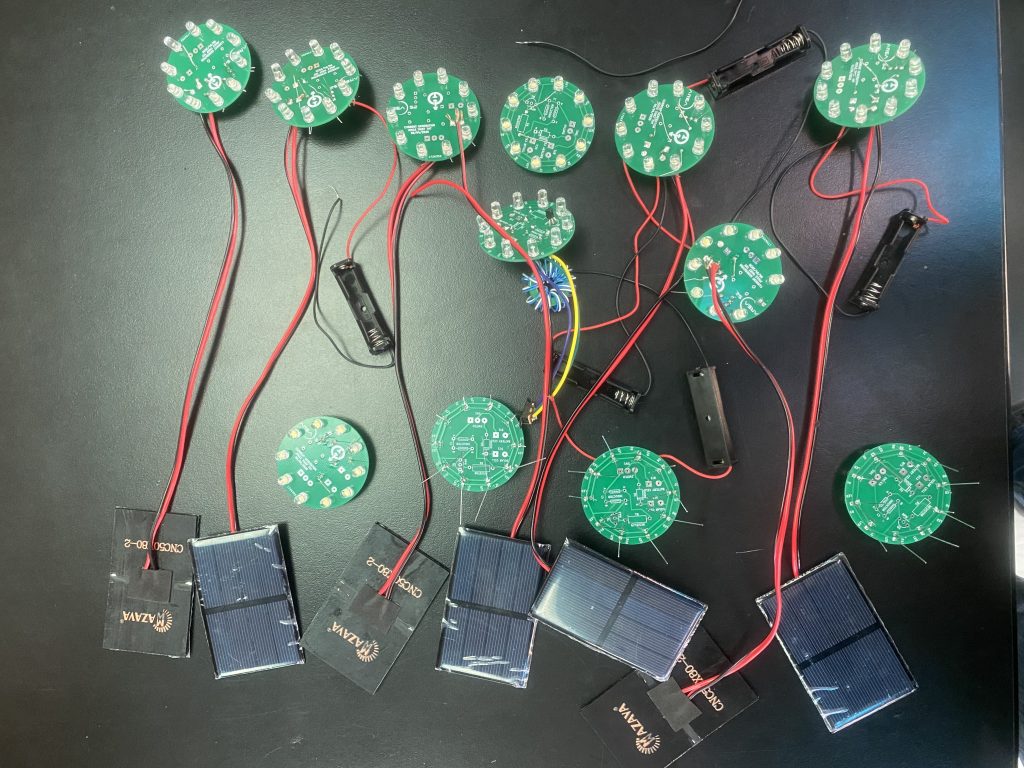

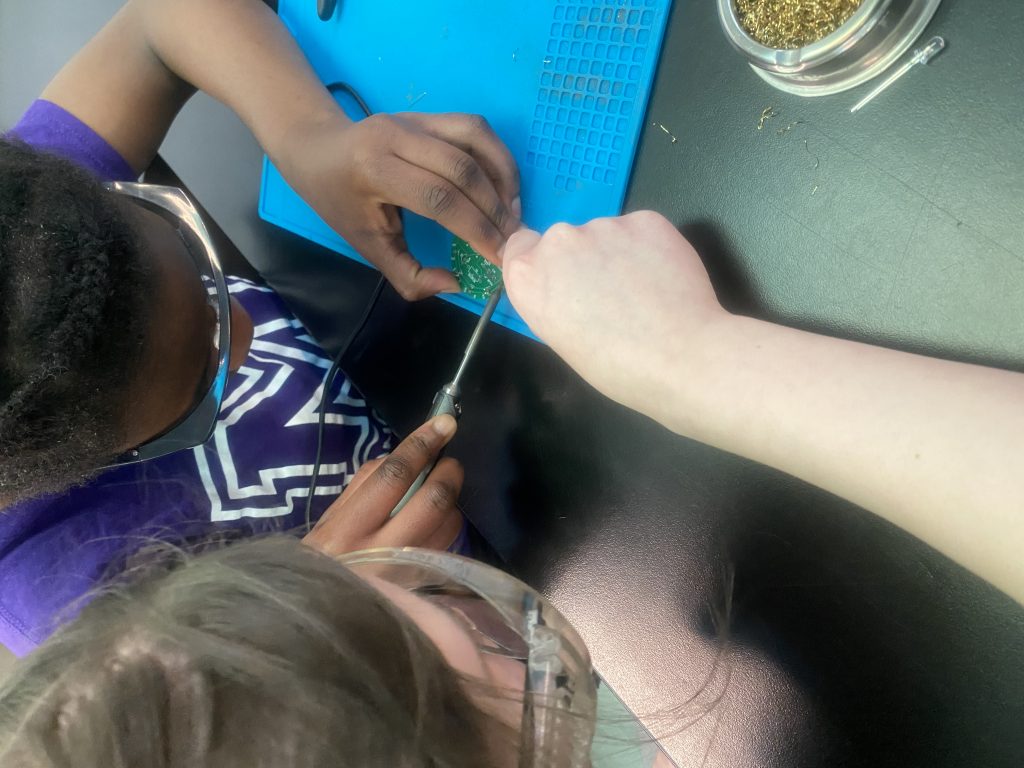

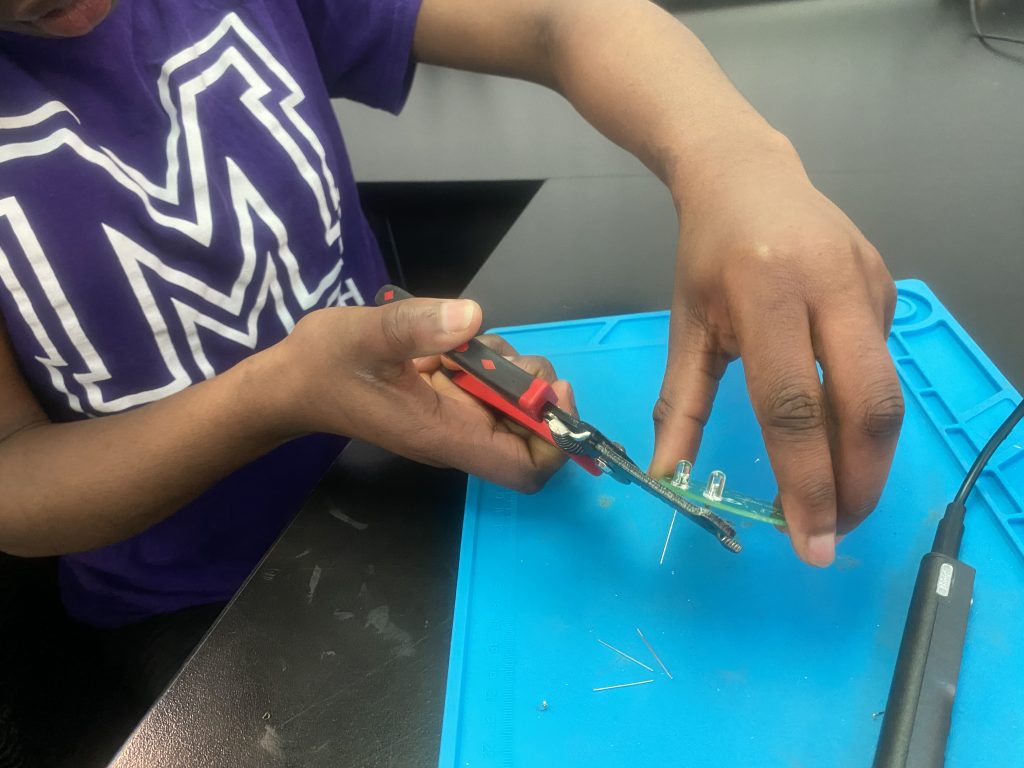

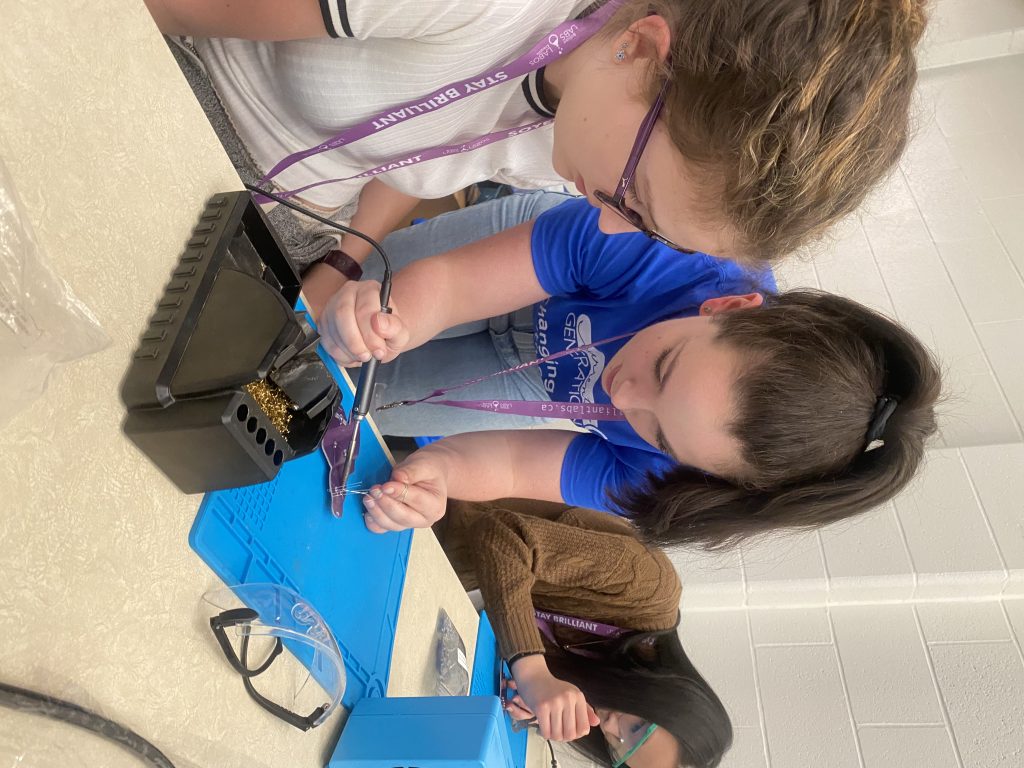

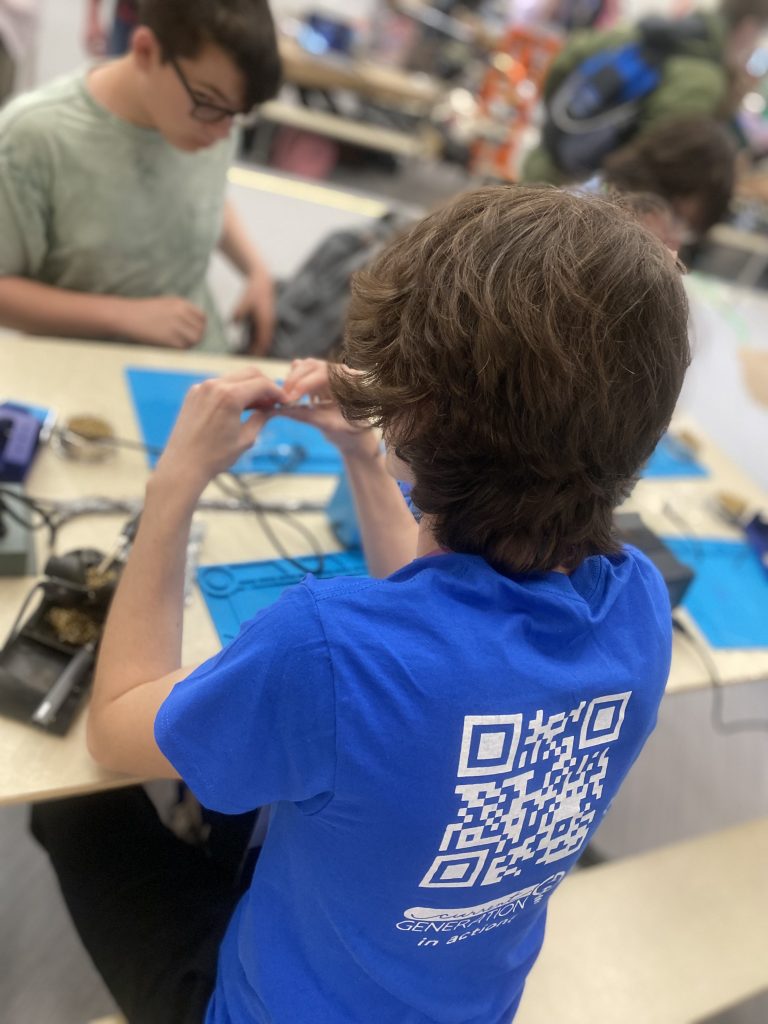

Grade 10 Science and Physics 12 students at MHS learn to solder and do good in the world at the same time. Made possible with funding and my new position at Brilliant Labs.

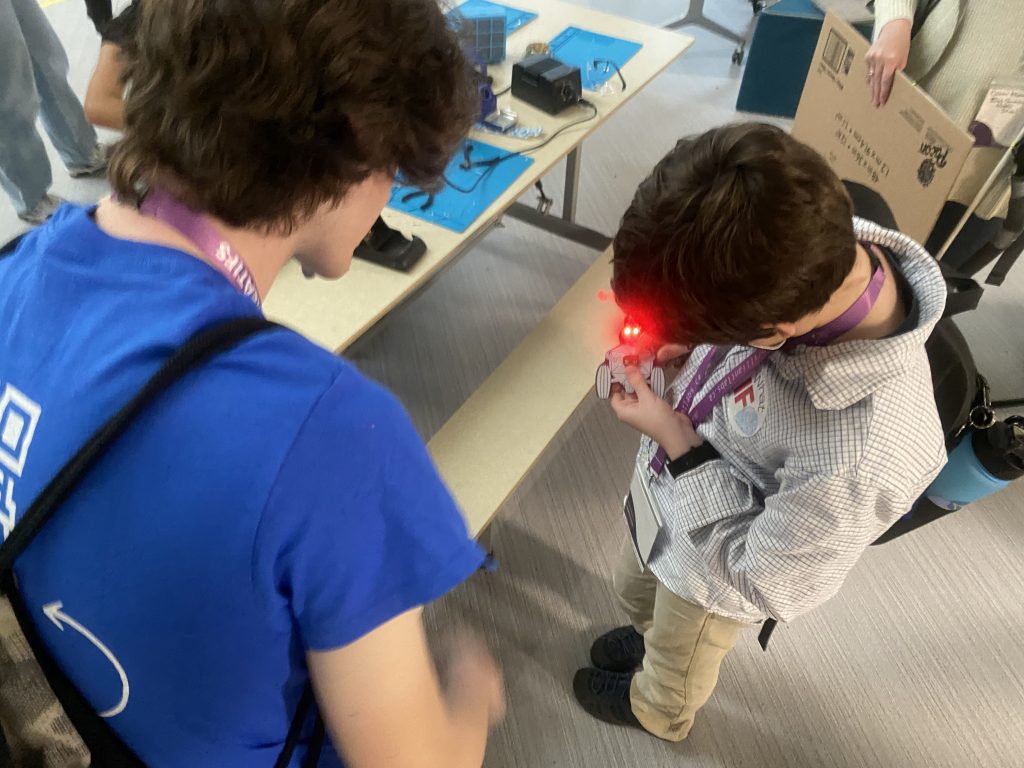

Current Gen students were asked to run a soldering station at the Brilliant Labs Atlantic Canadian Innovation Fair. The tables were busy all day long, even as students were being called to get on the buses to go home, we were still going strong. “This was so much better than I thought it would be.” “Now I can fix things.”

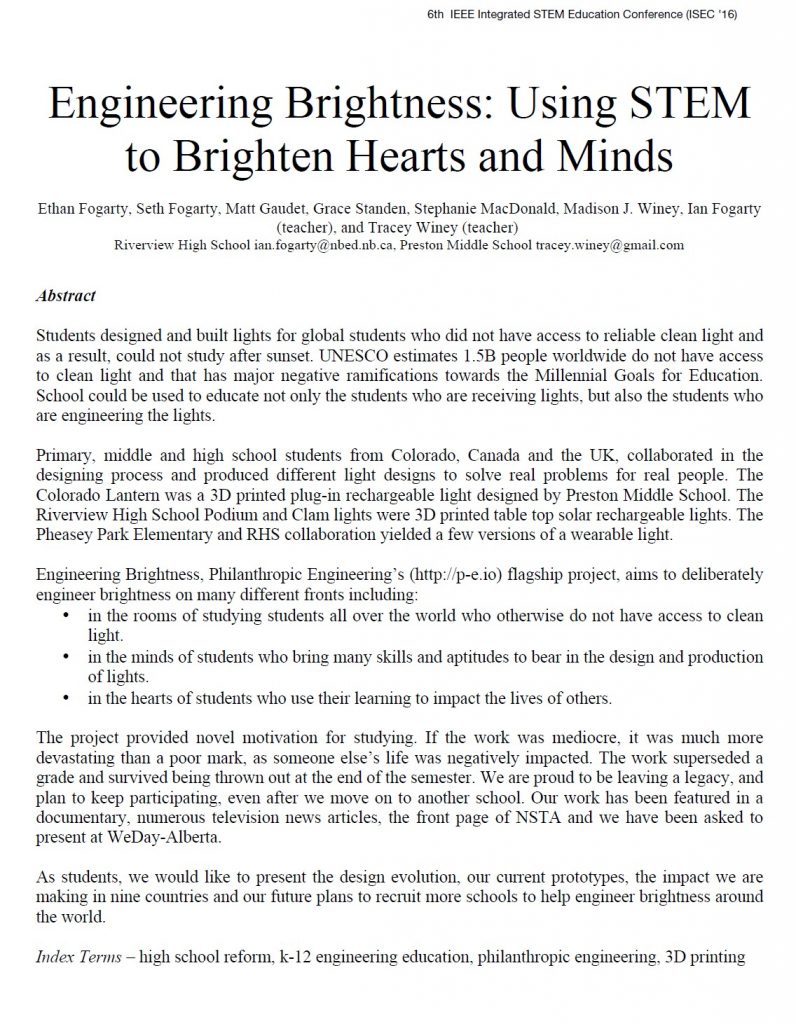

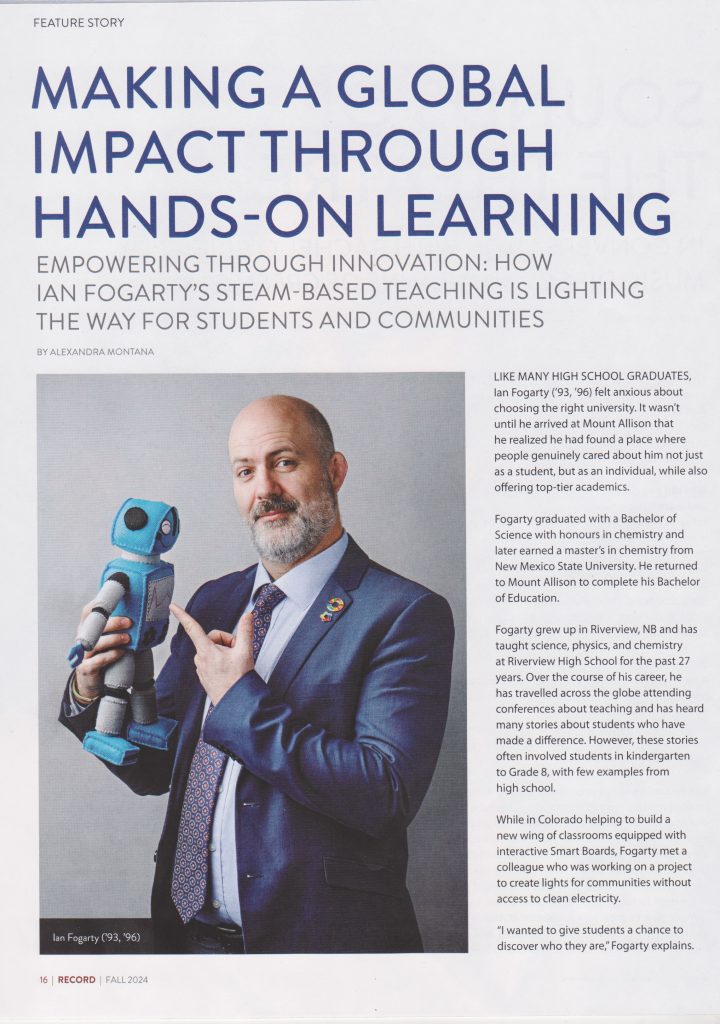

Please note that I am a CO-founder along with John Howe and Tracey Winey, both from Preston Middle School, Fort Collins Colorado.